Braille Embosser Speeds - How They Are Tested and Manipulated

Embossing Speed Claims – an explanation as to why Braillo is accurate and others are not

Out of the many performance specifications promoted by braille embosser manufactures, SPEED seems to be one of the most prominent. Why? Speed should be a straightforward characteristic that’s easy to understand: faster is better and worth paying for. The faster the embosser is, the more output it has, and therefore, the more documents you can produce. Speed also seems like an item that is relatively easy to measure – emboss this number of braille dots in this amount of time. Unfortunately, most embosser manufacturers take extreme liberties in both how they create “speed” and measure “how fast” they can emboss.

Keep this in mind:

- Is speed important if the braille quality is so bad you can hardly read it?

- Is it really a speed test if you are only embossing the exact same letter a thousand times as fast as you can?

- Lastly, how long can you hold your speed? Embossing for a few minutes at high speed and low quality is very easy. Embossing at high speed with perfect quality for hours straight… that is a different category altogether.

How to HONESTLY test and evaluate embossing speed that still maintains braille quality

Measurements

Embosser speeds are measured in CPS – Character Per Second, or PPH – Pages Per Hour.

These important attributes of a braille embosser should be straightforward to understand and measure, however, some manufacturers are quite misleading when determining these speeds.

Pages Per Hour (PPH):

This is very straightforward – how many braille pages your embosser can emboss in an hour. A normal and honest test of PPH would be to print real text transcribed from a book or document – you print for an hour and count the number of pages, which equals your PPH.

BUT…

If you wanted to promote an extremely high PPH, one could run the Form Feed command and not send ANY text to be embossed at all. In effect, it’s quickly feeding blank pages, therefore has a very high blank page PPH. While some manufacturers run blank pages to determine PPH, most will report incorrect speed ny only embossing a paragraph per page, instead of a full page of braille, which produces a similar misleading result.

When Braillo states PPH, it is based upon printing a full page of normal text for 60 minutes. That is the honest test of PPH, and an accurate PPH speed that can be replicated in the real world.

Manufacturer’s specifications aside, look at the quality of the braille embosser, its components and ask for real customer references. Production braille publishing requires the level of engineering found only in a Braillo. The inexpensive construction of solenoid-based embossers, or having a combination of solenoid-based embossers in a larger “box”, is not suited to withstand the heavy demands of true braille production.

Characters Per Second (CPS):

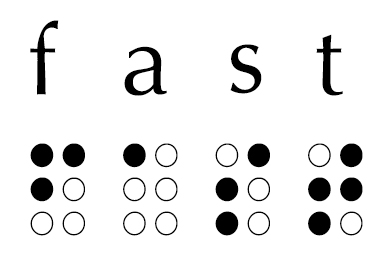

In a similar manner, some manufacturers will also be a bit vague about how they determine their cps speed. A braille cell is made up of 6 dots. http://www.brailleauthority.org/learn/braillebasic.pdf

The letter “a” is made up of only one dot, which is still considered a character. Competing embosser manufacturers will emboss a full page of the letter “a” to determine their top CPS speed, and this is what they promote in their advertising. Using a speed of 300 CPS as an example, do you want an embosser that can make 300 of the letter “a” per second? Probably not.

For an embosser to truly have an embossing speed of 300 CPS, it needs to be able to produce 300 characters per second, and a character is a combination of 6 dots. So the embosser must be able to produce 300 characters of 6 dots, or 1,800 braille dots per second. This is the proper way of determining CPS, and this is how Braillo determines our speed.

Manufacturer’s specifications aside, look at the quality of the braille embosser, its components and ask for real customer references. Production braille publishing requires the level of engineering found only in a Braillo. The inexpensive construction of solenoid-based embossers, or having a combination of solenoid-based embossers in a larger “box”, is not suited to withstand the heavy demands of true braille production.

Interested in the technical details when determining speed? Here they are!

Some of our competitors’ speed claims are both outrageous and physically impossible. Let’s look at a quick example:

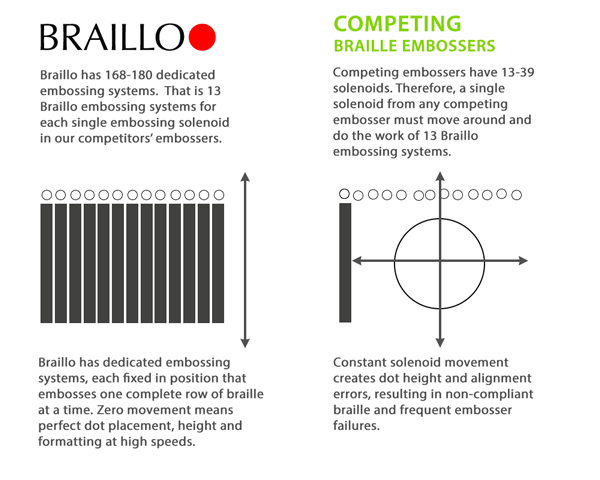

Braillo’s slowest embosser, the 300 S2, can produce 1,800 dots per second, because each of its 168 dedicated printing mechanisms can emboss at 10.71 rows of braille dots per second (1,800 CPS/168 Printing Mechanisms =10.71 rows per second). Remember, a Braillo embosses a complete row of dots on both sides of the page, one line of dots at a time, in every cycle. With our frequency at 10.71 Hz, the Braillo 300 S2 can emboss 3.33 complete lines of 84 full braille cells every 3.57 seconds, or 299.88 CPS.

Our competitor’s fastest embosser claims a speed of 330 CPS, yet they use only 39 solenoids which are split into 3 embosser heads. To emboss at their claimed speed of 330 CPS or 1,980 braille dots per second, each of these 39 solenoids will need to emboss a dot, and then the solenoid must move potentially the full width of a page to get to the next dot’s correct location, and emboss again. They claim they can do this at the incredible rate of (1,980 CPS/39 solenoids) = 50.76 times per second! This is impossible and the reason why many of these competing embossers fail – they are pushed to try and keep up with Braillo, but the inexpensive construction of solenoid-based embossers is not suited to withstand the heavy demands of true braille production.

Do not purchase a braille embosser until you have a manufacturer show you that they can achieve their claimed speeds, printing full braille cells for at least 1,000 printed pages, and do so without losing the quality of their braille. We invite you to test any Braillo against the competition so that you can see for yourself.

Braille embossing speed is an important feature of any braille embosser. When you can print at higher speeds over long periods, and keep your braille formatting quality high, you increase the profitability of your operations. This is one of the reasons manufacturers are so keen on inflating their speed claims. Only Braillo can engineer and construct production braille embossers with the high quality materials necessary to achieve true production speeds.