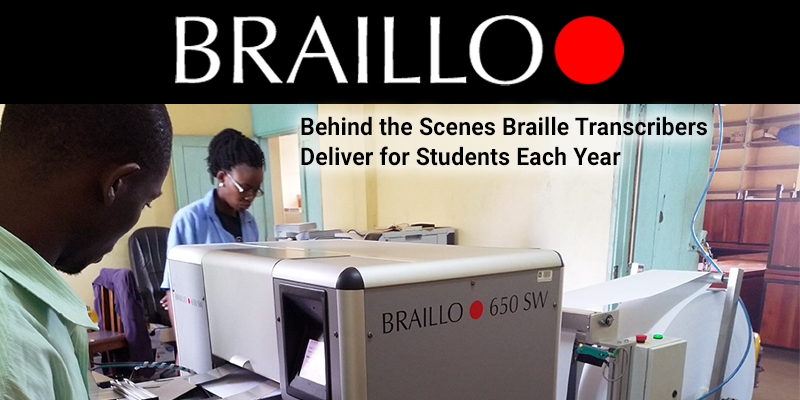

Braille Producers Make Education Happen

HURRY-HURRY-HURRY!

It seems like we are all in a HURRY! But, as the start of school approaches, Braillo would like highlight the truly noble efforts of braille production centers throughout the world who are in a tremendous hurry!

Many of these braille production centers work “around the clock” in August in order to finish their braille textbooks in time for September’s school start, and in some cases they may have only received the ink textbook master in as little as a week earlier!

It is distinguished efforts like these that help braille reading students perform better in school, and we would like you to join with us and salute them!

But did you know that preparation for August’s round the clock production starts long before the summer holidays?

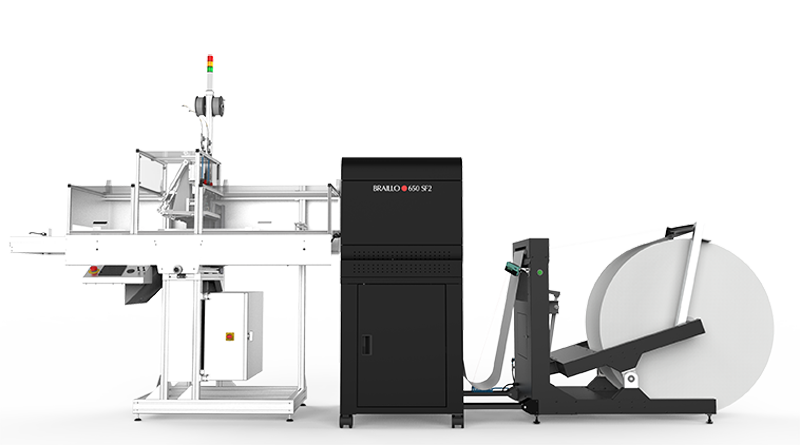

At Braillo’s factory, beside building each embosser with the rugged components necessary to tolerate 24/7 production, we check each embosser’s print shoes to ensure these have sufficient cup depth (0.58mm) to enable braille dots which exceed the braille authority’s minimum standards. We then check that our grooves will protect those dots from deformation when other dots are made nearby during the next embossing cycle. (see photo)

By doing so, we ensure that braille from our printer will be evenly high throughout page, throughout the book, and throughout the entire 24/7 production. And Braillo braille will ALWAYS exceed the braille authority’s standards. (This is not possible with the shallow cups that solenoid embossers require.) This is Braillo’s secret to producing the highest quality braille available. (And, we encourage you to have a test read of “Braillo Braille.” and we will be pleased to arrange a braille sample.)

Braille that exceeds the braille authority’s standards and is evenly high throughout the page is easier to read, and this helps student who are in a hurry-hurry-hurry to complete their reading by the assigned deadline.