Low Priced Braille Embossers Vs Long Lasting Braille Embossers

When it comes time to purchase a production braille embosser, nearly all potential customers evaluate the price above all else.

While in many cases, the lowest price is their deciding factor, the reality is that the lowest purchase price is not the lowest actual price. Below are the primary considerations that must be considered in order to evaluate the true cost of a production braille embosser.

As an example, one of Braillo’s competitors offers their attempt at a production embosser for $18,000. The specifications of this particular braille embosser line up with our Braillo 300 S2, which is $25,000. While they have the same embossing speed and physical dimensions, this is where the similarities between the two stops.

The Term "True Production Embosser" Comes From The Parts It's Comprised Of

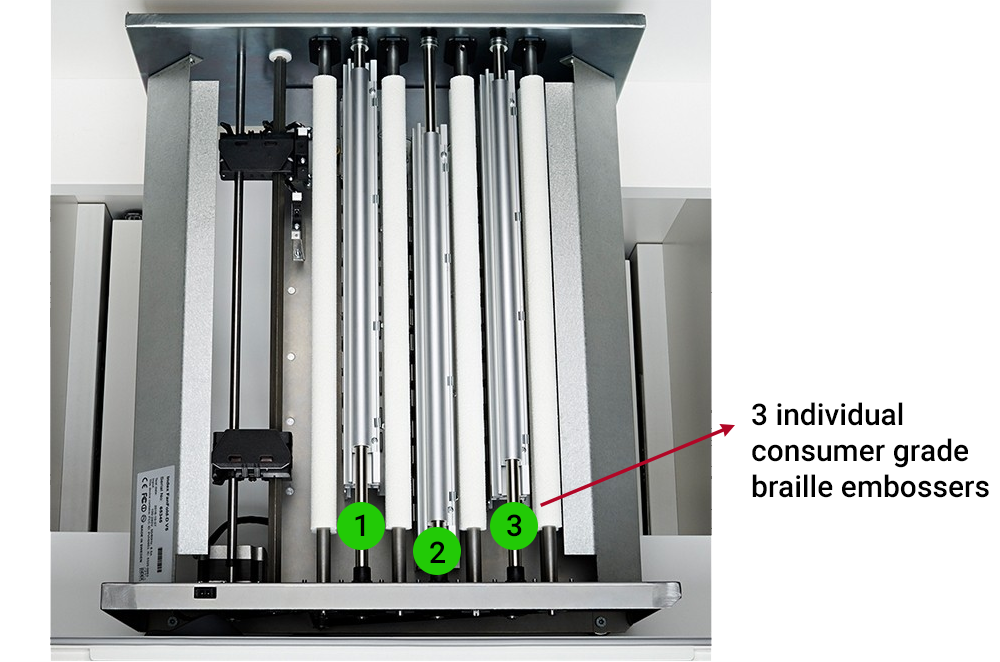

Personal Embossers Combined to Make a “Production” Embosser

The competition’s printer simply places 3 of their personal braille embossers in sequence to obtain their speed. Each personal embosser is 100 CPS, which is how they calculate the 300 CPS of their “production” embosser. It uses the same parts found in the personal braille embossers with the main difference being that they have put them into one larger case to make the overall appearance more robust.

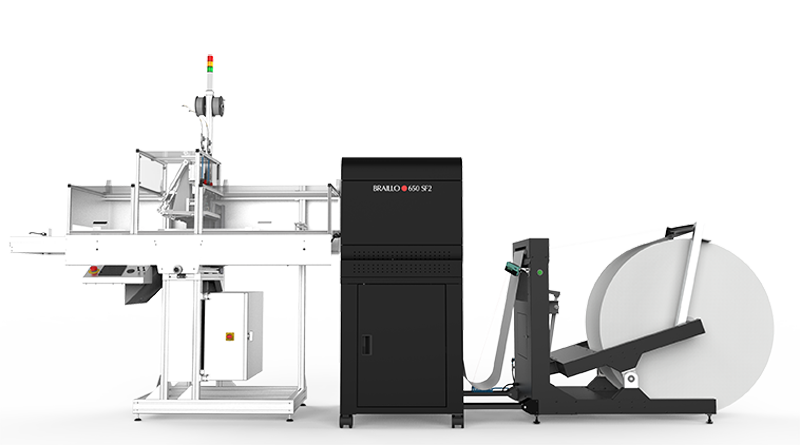

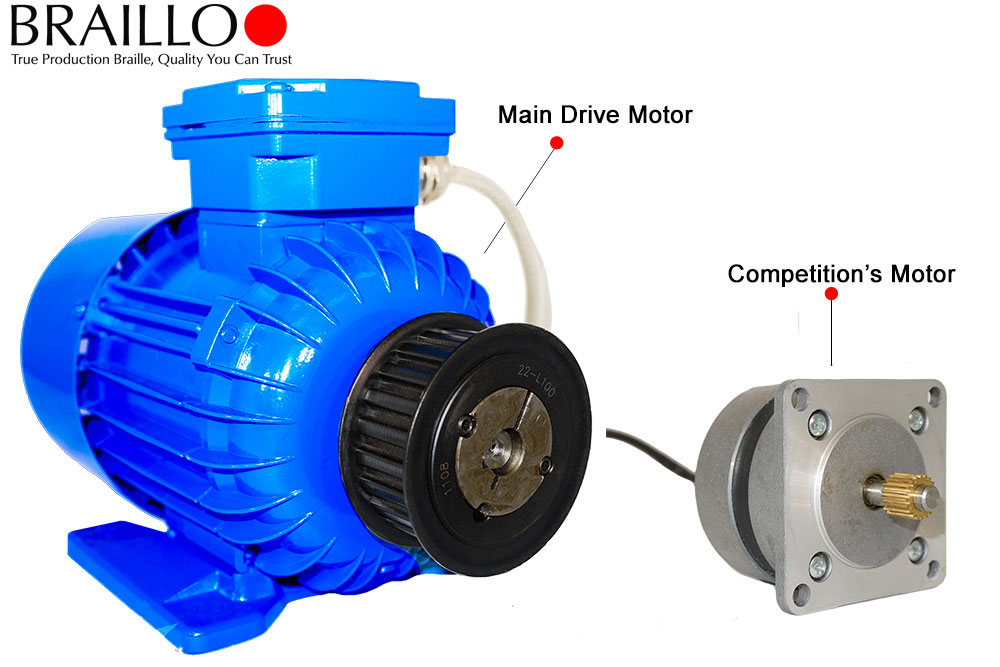

In comparison, the Braillo 300 S2 is an embosser purposefully built for all day, high speed, true braille production – it uses hardened steel parts, has durable components, powerful motors, etc. See compare Braillo’s build quality to the competition here.

Solenoids Can’t Handle The Heat

Using a “production” embosser made up of individual personal embossers at true production levels is a recipe for failure. This production level would require the solenoid-based competition to run for hours straight, which is impossible for embossers using this technology.

These embossers must be intermittently “cooled” to ensure accurate, properly formed and aligned braille cells – and anybody saying otherwise is not telling the truth. No solenoid can emboss for hours at a time without overheating and causing poor braille output.

Once these “production” embossers overheat and fail because they cannot meet the advertised workload, the owner of that embosser would seek factory warranty support.

Braille Embosser Warranties Matter

Our competition’s warranty support is handled by the dealer and not the manufacturer, which costs the dealer time and money. Since the dealer is motivated to sell more embossers, there is no incentive for them to get your problem corrected in a timely manner. This means more downtime and hassle for you, and downtime costs you real money. How much would it cost you if your embosser was down for a week? Braillo has the industry’s best warranty at up to 4 years and is fully factory supported. Braillo stands behind our embossers 100%. See Braillo’s detailed warranty here

Replacing Unreliable or Failed Braille Embossers

In most cases, little can be done to remedy the problem because the lightweight components are simply worn out. The customer therefore only has only two options – replace parts and assemblies at a high price, or replace the entire embosser! Again, more downtime and now the reality of having to spend considerable money on parts, labor and/or a new embosser.

This scenario outlined above will happen over and over again if you attempt to push true production levels on a competitor’s “production” embosser.

Meanwhile, in this example, the Braillo 300 S2 is still like-new after millions of embossed pages. Braillo embossers are built to last decades and produce millions of pages before needing service.

Making The Right Choice

The clear take-away is this: the low initial purchase price for the competition’s “production” embosser (made up of personal embossers) is far more expensive than a Braillo.

Poor braille quality, failing parts, overheating issues, slow repair and eventual replacement all mean significant downtime and money. Combine this with a weak warranty that is serviced by reluctant dealers, and you will undoubtedly be paying considerably more than the price of a Braillo.

The question you must ask yourself is this.

Do I try and save $7k dollars today on a recently created, consumer grade embosser that I intend to run at production levels and hope it works, hope I’m supported when it fails and hope my production lines don’t come to a halt?

Or do I go with a Braillo, whose embossers are specifically built for true production braille and have been for 30 years, can be used 24/7 at high speed, are used by all the largest braille production facilities, last decades and are fully supported with up to a 4 year warranty direct from the manufacturer?

We feel the answer is clear and if you check references, they will tell you for themselves. We will be pleased to provide references for customers that have mistakenly purchased a competing “production” embosser and have since switched to Braillo. Trust what all the industry leaders use for their businesses – trust in a Braillo.